Design, Implement, and Optimize Advanced Control Systems for Industrial Environments

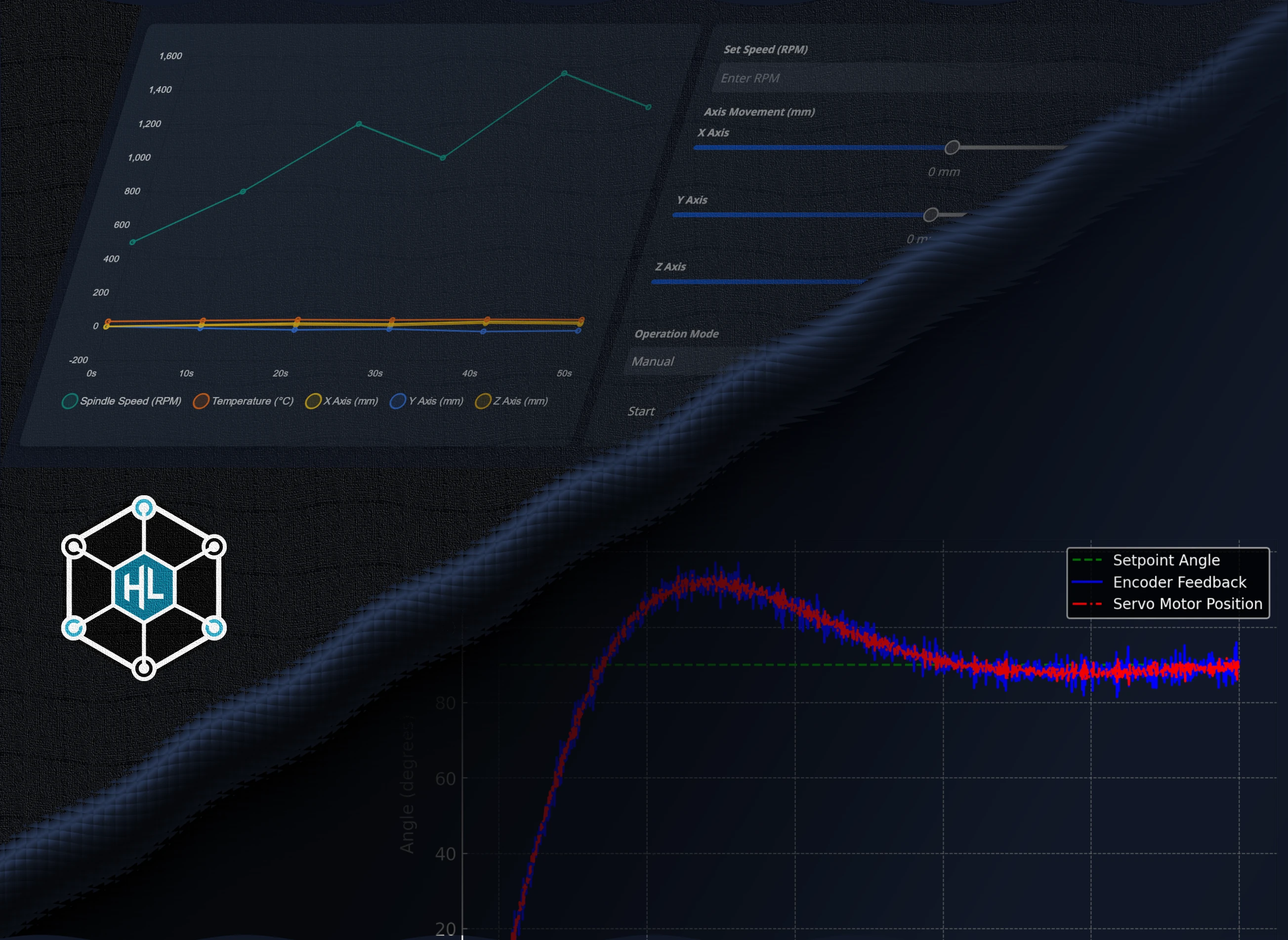

- Develop Control Systems:

Expertise in designing and implementing control systems for industrial processes, including process automation, manufacturing systems, and production lines. Proficient in PLC programming, SCADA systems, and custom control algorithms to ensure precise and reliable system operation. - Implement Real-Time Systems:

Develop real-time systems to meet the stringent timing and reliability requirements of industrial automation. Implement real-time operating systems (RTOS) for seamless synchronization of hardware, sensors, actuators, and control systems in critical applications. - Sensor & Actuator Integration:

Integrate a wide variety of sensors (temperature, pressure, proximity, flow, etc.) and actuators (motors, valves, etc.) for automated monitoring and control. Ensure accurate data acquisition, signal processing, and real-time system response to drive automation efficiency. - Simulation Development:

Create simulation models for system testing and validation, allowing for the modeling of industrial processes and control algorithms before physical deployment. Use simulation software to test system behavior under different scenarios, ensuring safety and performance optimization in real-world applications. - Mission-Critical Software:

Develop mission-critical software that ensures high availability, fault tolerance, and safety in industrial environments. Implement redundancy, error detection, and recovery mechanisms to prevent downtime and ensure continuous operation of critical systems. - Automation System Design:

Design comprehensive automation systems, including both hardware and software components. Utilize industry standards such as Modbus, OPC-UA, and Ethernet/IP for communication between devices and integration with enterprise-level systems. - Embedded Systems Development:

Develop embedded solutions for industrial automation, ensuring low-latency control and real-time performance. Optimize software for resource-constrained devices, from microcontrollers to industrial PCs, and integrate with sensors, actuators, and communication networks. - IoT Integration for Industrial Automation:

Incorporate IoT technology into industrial automation systems to enhance remote monitoring, predictive maintenance, and data analytics. Enable connectivity to cloud platforms and integrate industrial data with enterprise systems for improved decision-making and process optimization. - Safety and Compliance:

Design systems in accordance with industry safety standards (e.g., IEC 61508, ISO 13849) to ensure safe operation of automation systems. Implement safety protocols for emergency shutdowns, fail-safes, and operator alerts to minimize risks. - Energy Management:

Implement automation systems to optimize energy usage in industrial processes. Use energy monitoring systems to track consumption and reduce operational costs while improving efficiency and sustainability. - System Integration & Communication:

Ensure smooth integration between automation systems and existing infrastructure. Develop communication protocols and interfaces for seamless interaction with enterprise-level software, including MES (Manufacturing Execution Systems), ERP (Enterprise Resource Planning), and other business systems. - Predictive Maintenance & Data Analytics:

Use machine learning and data analytics to develop predictive maintenance solutions for industrial machinery. Analyze real-time data from sensors to predict equipment failure, optimize maintenance schedules, and reduce downtime. - Performance Tuning & Optimization:

Conduct performance analysis and tuning of control systems to ensure they meet required throughput, accuracy, and efficiency standards. Use PID controllers, adaptive control, and other optimization techniques to fine-tune system parameters and improve overall system performance. - Custom Automation Solutions:

Work with clients to develop tailored automation solutions that address specific needs, whether it's improving an existing system, integrating new technologies, or optimizing workflows in highly specialized industries like manufacturing, energy, or logistics.